-

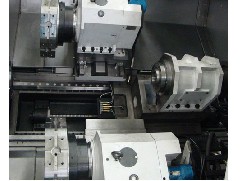

Nc machine tools and the comparison of ordinary machine tools

2020-06-22 619

1. Precision of the upper handOrdinary lathe by gear quiet every screw and nut. As the gap between vice, plus manual manipulation is not correct, so the repeat precision is low. Ordinary lathe measur

-

Stainless steel welded joint should be how to deal with?

2020-06-22 582

Stainless steel welded joint should be how to deal with?The polishing of stainless steel weld joint for flat parts must be polished after welding, grinding should be butt head flattening before (she

-

Laser welding of stainless steel pipe welding method

2020-06-22 666

【 welding knowledge 】 the laser welding of stainless steel pipe welding methodLaser weldingIn all of the steel pipe welding application, the edge of the steel strip to melt, when use the clamp bracke

-

Nc machine tools how to maintenance

2020-06-22 611

数控车床平时养护 1、天天做好各导轨面的清洁光滑,有主动光滑体系的机床要守时查看、清洁主动光滑体系,查看油量,及时增加光滑油,查看油泵是不是守时发动打油及中止。 2、天天查看主轴箱主动光滑体系作业是不是正常,守时更换主轴箱光滑油。 3、留意查看电器柜中冷却电扇是不是作业正常,风道过滤网有无阻塞,清洁沾附的尘土。 4、留意查看冷却体系,查看液面高度,及时增加油或水,油、水脏时要更换清洁

-

Nc machining experience

2020-06-22 642

Because of the complexity of the numerical control processing, such as different machine, different materials, different cutting tool, different cutting way, different parameter Settings, etc.), the

-

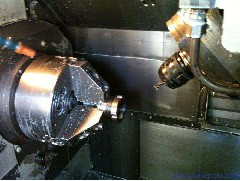

Numerical control lathe processing

2020-06-22 542

Numerical control lathe processing is a kind of high-tech processing method of fine metal parts. The numerical control lathe processing a variety of examples of 316 or 304 stainless steel, carbon ste

-

How do I select the cutting dosage of CNC lathe processing?

2020-06-22 555

对付高服从的金属切削加工来说,被加工质料、切削东西、切削条件是三大概素。这些决定着加工时间、刀具寿命和加工质量。经济有用的加工方法一定是公道的选择了切削条件。 切削条件的三要素:切削速率、进给量和切深直接引起刀具的毁伤。陪同着切削速率的进步,刀尖温度会上升,会孕育发生机盼望械的、化学的、热的磨损。切削速率进步20%,刀具寿命会淘汰1/2。 进给条件与刀具背面磨损干系在小的范畴内孕育发生。

-

The nc lathe turning processing technological process

2020-06-22 494

当加工五金配件,常用的机械设备是数控车床,数控车床车削加工硬,效率高,加工精度高,表面形状复杂,与普通车床的加工相比具有质的飞跃。然而,当数控车床车削加工流程编排是非常重要的。我们也遇到了同样的机床设备相同的产品,加工,由于加工工艺的不同,加工的产品质量有很大的差别。 理想的加工程序不仅应保证符合合格文物的模式,应该可以使数控机床的功能有合理的应用,并给出了充分发挥。数控机床是一种效率的自